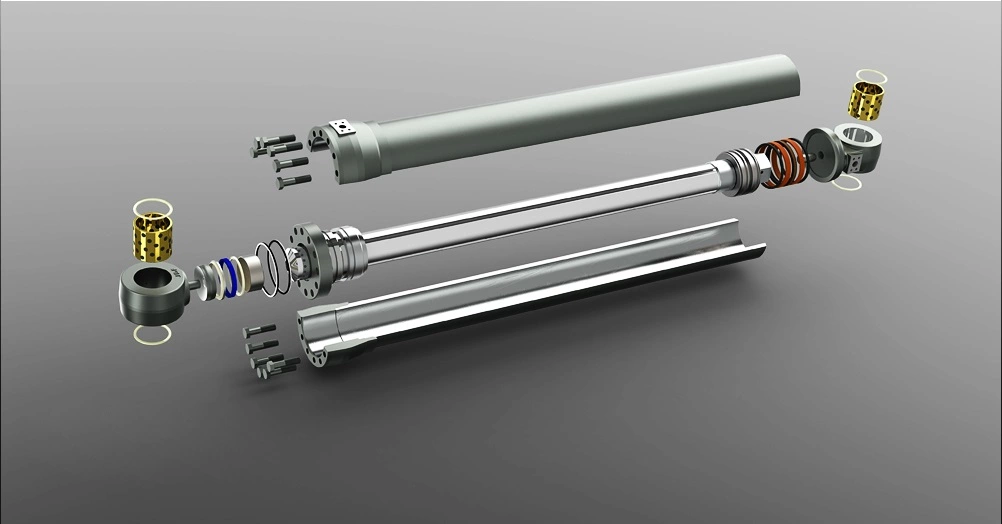

Hydraulikarm-Zylinderbaugruppe vom chinesischen Hersteller von Hydraulikarm-Zylinderbaugruppen, ist ein wesentlicher Bestandteil in hydraulischen Systemen. Die Baugruppe besteht aus einem Zylinder, ein Kolben, eine Kolbenstange, und verschiedene Siegel. The hydraulic arm cylinder assembly is responsible for the movement of the arm in various hydraulic machines. Understanding the hydraulic arm cylinder assembly is essential for hydraulic system design, maintenance, and repair. In diesem Artikel, we will discuss how to understand the hydraulic arm cylinder assembly. Also includes its components, and its operation.

Components of Hydraulic Arm Cylinder Assembly:

- Cylinder: The cylinder is the main component of the hydraulic arm cylinder assembly. It is a closed tube that houses the piston and the piston rod.

- Kolbenstange: The piston rod is a long rod that is attached to the piston. It is responsible for transmitting the mechanical force produced by the piston.

- Kolben: The piston is a cylindrical-shaped component that moves inside the cylinder. It is responsible for converting the hydraulic pressure into mechanical force.

- Robben: Seals are critical components of the hydraulic arm cylinder assembly. They are responsible for preventing the leakage of hydraulic fluid from the cylinder.

Understanding the Operation of Hydraulic Arm Cylinder Assembly:

The hydraulic arm cylinder assembly operates based on the principles of fluid mechanics. When hydraulic fluid is pumped into the cylinder, es übt Druck auf den Kolben aus. The piston moves in the cylinder, which transmits the force to the piston rod. The piston rod then moves the arm in the hydraulic machine.

The hydraulic arm cylinder assembly works on the principle of Pascal’s law. This principle states that pressure applied to a fluid in a closed system will be transmitted equally in all directions. In the case of the hydraulic arm cylinder assembly, the pressure applied to the hydraulic fluid in the cylinder is transmitted equally to the piston. Then piston may operate to moves the arm.

Maintenance and Repair of Hydraulic Arm Cylinder Assembly:

Hydraulic arm cylinder assemblies require regular maintenance to keep them functioning properly. Seals in assemblies must be checked regularly and replaced if necessary to prevent hydraulic oil leakage. Cylinders and pistons, from China hydraulic arm cylinder assembly Manufacturer, must also be checked for wear and replaced if necessary.

If the hydraulic arm cylinder assembly is not functioning correctly, it may require repair. The repair process involves disassembling the cylinder, replacing any damaged components, and reassembling the assembly. It is essential to follow the manufacturer’s instructions while repairing the hydraulic arm cylinder assembly.